I am a cryogenics researcher driven by curiosity and purpose—working to make cooling systems more efficient, compact, and sustainable. My academic path began with a BTech from the Indian Institute of Technology Madras and continued through a PhD that included research at the National Institute of Standards and Technology (NIST, USA), where I contributed to high-frequency pulse tube cryocooler development. After my PhD, I worked at the Energy research Centre of the Netherlands (ECN), bringing an industrial mindset into academic research.

At the University of Twente, I lead the Applied Thermal Sciences group, where we develop next-generation cryogenic technologies to support advances in science, energy, and high-tech systems. My core expertise lies in cryocoolers, and I work across both regenerative types (including Stirling and pulse tube) and recuperative types (such as Joule-Thomson). Our team develops cryogenic gas circulators, mechanical heat switches, and advanced thermal interfaces—technologies that are foundational to enabling high tech systems, quantum computing, and low temperature instrumentation.

A significant focus of our current research is liquid hydrogen, where we coordinate several national and international initiatives aimed at building energy-efficient, safe, and scalable cooling and transport systems. These efforts support the Netherlands’ ambitions in the hydrogen economy and reinforce our role as a European leader in cryogenic innovation.

I strongly believe that today’s cryogenic systems must evolve. Many existing “dry” cryogenic platforms resemble early computer systems—bulky, tightly integrated, and difficult to adapt or maintain. As demand grows for scalable, modular, and serviceable cooling systems in areas like quantum technologies, high-tech systems, and accelerator-based research, the cryogenics community must deliver a transformative shift. Our work aims to enable that shift—not through incremental improvement, but through fundamental rethinking of how cooling systems are designed and integrated.

Beyond research, I actively serve the international cryogenics community. I currently chair the Cryogenic Society of Europe, sit on the Board of Directors of the Cryogenic Engineering Conference (CEC), and represent the Netherlands at the International Institute of Refrigeration (IIR). I’m deeply committed to building strong collaborations—connecting Dutch excellence with global partners—and to mentoring the next generation of scientists and engineers who will shape the future of thermal sciences.

Cryogenics, to me, is not just about achieving low temperatures. It’s about unlocking new frontiers in technology and sustainability—by reimagining how we move, manage, and harness cold.

For more info about Srinivas Vanapalli on the 'Featured Scientists' page, click below:

Expertise

Physics

- Temperature

- Cooling

- Heat

- Gaseous State

- Ice

- Performance

- Liquid Nitrogen

Engineering

- Microcooler

Organisations

Revolutionizing Cryogenic Cooling: Towards Energy-Efficient, Scalable, and Compact Systems

Cryogenic cooling technology has remained largely unchanged for decades, while other fields, like computing, have undergone dramatic transformations—from room-sized mainframes like ENIAC to compact, energy-efficient mobile devices. The Applied Thermal Sciences (ATS) Group at the University of Twente is driving a similar revolution in cryogenics, shifting the focus from purely achieving low temperatures to optimizing energy efficiency, compactness, and scalability.

Today's cryocoolers are highly inefficient, often consuming up to 8.0 kW of input power just to achieve 1 W of cooling at 4 K. This inefficiency limits the widespread adoption of cryogenic technologies in high-tech applications such as quantum computing, superconducting systems, electron microscopy, and hydrogen energy systems.

Our mission is to fundamentally rethink cryogenic cooling, making it as efficient, compact, and widely accessible as modern electronics. We are actively developing:

✔ Next-generation energy-efficient cryocoolers, with a targeted 50 % reduction in power consumption.

✔ New thermal management solutions, including heat switches, cryogenic circulators, and advanced thermal interfaces.

✔ Establishing energy efficiency labeling system for cryogenics, setting a new industry standard for sustainability.

✔ Distributed, modular cryogenic cooling systems to minimize energy losses and improve reliability.

Our work is bridging the gap between fundamental thermal sciences and industrial application, ensuring that cryogenic cooling evolves into a high-performance, sustainable, and scalable technology for the 21st century.

Research Landscape

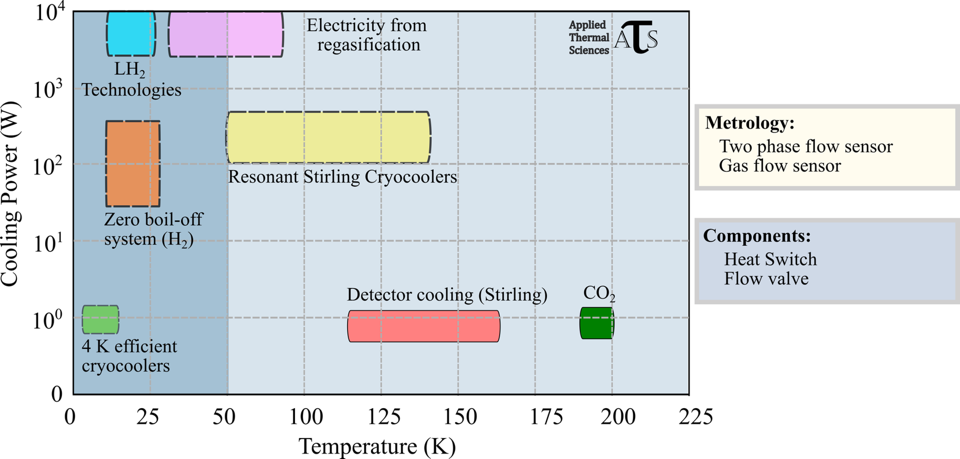

The figure below illustrates the range of cryogenic cooling technologies that our group is actively researching, categorized by temperature range and cooling power:

Key Research Topics

✔ 4 K Efficient Cryocoolers

Developing highly efficient cryogenic refrigeration systems for quantum computing, superconducting devices, and space applications.

✔ Zero Boil-Off Hydrogen Systems

Innovating solutions to prevent hydrogen losses in storage and transport, improving the sustainability of liquid hydrogen (LH₂) infrastructure.

✔ LH₂ Technologies & Electricity from Regasification

Exploring hydrogen liquefaction, transport, and energy recovery through cryogenic heat exchangers, cryogenic Stirling electricity generator, enhancing the hydrogen economy.

✔ Resonant Stirling Cryocoolers

Optimizing compact, high-efficiency Stirling cryocoolers for healtcare, lifesciences, and industrial applications.

✔ Detector Cooling (Stirling Cryocoolers)

Advancing thermal control for infrared, space, and scientific detectors.

✔ CO₂ Cryogenic Applications

Investigating cryogenic carbon capture and storage (CCS) technologies, contributing to climate mitigation efforts.

Enabling Technologies

Our research is supported by state-of-the-art metrology and component development, including:

- Two-phase and gas flow sensors for precise cryogenic fluid management.

- Cryogenic heat switches and flow valves for advanced thermal control in extreme environments.

Ongoing Projects & Collaborations

Our research is actively supported by projects funded through:

- High Tech Systems & Materials (HTSM) programs

- European Union (EU) research initiatives

- Netherlands Enterprise Agency (RVO) grants

We are pioneering new cryogenic cooling systems and innovative liquid hydrogen technologies, aiming to push the boundaries of energy efficiency and system performance.

Join Us – Open Opportunities for Students & Researchers

Are you a motivated student or researcher passionate about cryogenics, thermal management, and energy-efficient cooling?

At ATS, you will have the opportunity to:

✔ Work on cutting-edge cryogenic technologies with real-world impact.

✔ Collaborate with leading academic and industrial partners.

✔ Gain hands-on experience with state-of-the-art experimental setups and modeling tools.

✔ Contribute to next-generation cooling solutions for quantum computing, space technology, and hydrogen energy.

🔹 We offer opportunities for:

- Bachelor & Master thesis projects

- Research internships

Interested? Reach out to Prof. dr. ir. Srini Vanapalli for more information!

Publications

2026

2025

Research profiles

What defines me as a teacher?

- Experiment with better ways to achieve success

- Value the students and respect them.

- Inspire students by drawing parallels between the subject matter and students everyday experiences. Also walking through several examples.

- Belief in mentoring students and showing them the path to learn themselves.

- Provide thought provoking examples (not just a text book).

Affiliated study programs

Courses academic year 2025/2026

Courses in the current academic year are added at the moment they are finalised in the Osiris system. Therefore it is possible that the list is not yet complete for the whole academic year.

- 193599010 - Internship

- 193599039 - Master Thesis: Physics Aspects

- 193599089 - Master Thesis: General Aspects

- 201700027 - Master Graduation Assignment

- 201700185 - Internship

- 201800344 - Master's Assignment: Physics Aspects

- 201800345 - Master's Assignment: General Aspects

- 201900284 - Placement Course for Exchange Students

- 202000677 - Thermodynamics

- 202000680 - Project Thermodynamics

- 202000716 - Bachelor Assignment

- 202001433 - Bachelor’s Assignment AM-AP

- 202100230 - Studytrip Course AT

- 202200185 - Classical Thermodynamics

- 202400605 - Cooling Science and Technology

Courses academic year 2024/2025

- 193599010 - Internship

- 193599039 - Master Thesis: Physics Aspects

- 193599089 - Master Thesis: General Aspects

- 201700027 - Master Graduation Assignment

- 201700185 - Internship

- 201800344 - Master's Assignment: Physics Aspects

- 201800345 - Master's Assignment: General Aspects

- 201900284 - Placement Course for Exchange Students

- 202000670 - Bachelor Assignment

- 202000677 - Thermodynamics

- 202000680 - Project Thermodynamics

- 202000716 - Bachelor Assignment

- 202001433 - Bachelor’s Assignment AM-AP

- 202100230 - Studytrip Course AT

- 202200185 - Classical Thermodynamics

- 202400605 - Cooling Science and Technology

My research is supported by national, european funding agencies and industry.

Funding entities: NWO-TTW, EU, TKI-HTSM, TKI-Energy, ZonMW, ESA & Air Liquide

What drives me as a scientist is the exciting wealth of knowledge and surprises I come across in my research, either in the lab or in discussions with my team. We built a little cryogenic fluids playground and often me and my students try things out of curiosity, very often transforming into serious multi-year projects. I believe in sharing this curiosity with the general public and to high-school students, with a hope to ignite the STEM flame in them. My outreach efforts were recognized recently by the MESA+ Dave Blank Outreach Award.

In the press

News feature on HTSM website: https://hollandhightech.nl/nieuws-agenda/nieuws/mijlpaal-in-cryogene-koeling

News feature in Physicsworld (IOP publishing)

Why insulated metals cool down faster than their bare counterparts: https://physicsworld.com/a/why-insulated-metals-cool-down-faster-than-their-bare-counterparts/

Study of liquid-nitrogen droplets gives new insight into cryogenic spray-cooling: https://physicsworld.com/a/study-of-liquid-nitrogen-droplets-gives-new-insight-into-cryogenic-spray-cooling/

UToday: Freeze!: https://www.utoday.nl/science/67723/freeze

August and October 2019 COLDFACTS issue (https://cryogenicsociety.org/cold_facts/)

News on utwente.nl

Mulholland memorial award for Srinivas Vanapalli

Address

University of Twente

Carré (building no. 15), room C2049

Hallenweg 23

7522 NH Enschede

Netherlands

University of Twente

Carré C2049

P.O. Box 217

7500 AE Enschede

Netherlands