Wouter Grouve received his PhD degree with honors in 2012 on the topic of advanced fiber placement of thermoplastic composites. He was then employed by the ThermoPlastic composites Research center, before returning to the University of Twente in 2018 to take up a role as an assistant professor in the field of thermoplastic composites. His research efforts revolve mostly around the processing of thermoplastic composites, with the aim to develop predictive simulation tools that allow first-time-right manufacturing.

Wouter has received the ESAFORM PhD Prize for Industrial Research and the IOM Composite award in 2014 and is a member of the program committee of the ITHEC conference on thermoplastic composites.

Expertise

Material Science

- Composite Material

- Thermoplastics

- Fiber

- Tape

- Consolidation

- Friction

- Fracture Toughness

Engineering

- Thermoplastic Composite

Organisations

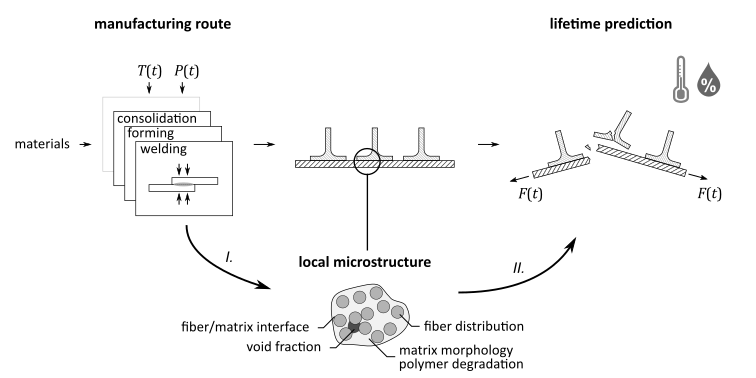

My research activities revolve around the manufacturing and performance of composite parts and structures, with a specialization in thermoplastic composites. I am particularly interested in the influence of the manufacturing process on the performance of the final part. Progress in this field requires a structured two-step approach that is outlined in the figure below. First, we need to understand how the processing history affects the material’s microstructure, in which microstructure is defined broadly and encompasses properties such as void fraction, crystalline morphology and fiber-matrix distribution. Secondly, we need to understand how this microstructure affects the (mechanical) performance on a macro-scale.

The performance of a composite component is determined by its microstructure, which then again strongly depends on the raw materials used and the chosen manufacturing route.

A proper description of the interrelations between process, microstructure and performance requires a sound understanding of the underlying physical mechanisms. I rely on experiments, often combined with simple models, to identify and analyze these mechanisms. Our laboratory is well equipped for this task with access to all relevant processing equipment for (thermoplastic) composites. Moreover, our group has a strong background in the development of special-purpose test setups to analyze material behavior for which no standard procedure exists. Once well understood, the relevant mechanisms are implemented in predictive models for use by the industry in order to optimize either the materials used, the processing route or the design of the final component.

I have worked on several manufacturing processes for thermoplastic composites, including laser-assisted fiber placement, over-injection molding, co-consolidation of metal-composite joints, stamp forming, autoclave consolidation, and welding. Currently, I am working on press forming of fiber-placed blanks, vacuum-bag-only consolidation and co-molding of metal inserts. Moreover, I am also involved in two projects focusing on predictive (long-term) performance of thermoplastic composites.

Are you interested to learn more about my research activities or looking to collaborate? Please feel free to contact me.

Publications

2025

Research profiles

I am involved in the following educational activities:

- Composites (191121710) The course provides an introduction into the mechanical behavior of and manufacturing processes for continuous fiber reinforced composite structures. The main theoretical part deals with the Classical Lamination Theory. It starts from constituent properties, via the mechanical behavior of a single ply, to the thermo-mechanical behavior of a laminate. Moreover, the failure of such materials is also highlighted.

The course also gives the opportunity to apply the acquired knowledge to some applications. This includes a set of labworks both modeling oriented (Finite Element Analysis) and experimentally oriented (composites manufacturing and mechanical testing).

- Aircraft Engineering (202000158) The minor Aircraft Engineering teaches students about the basic concepts of aircraft design, including topics aerodynamics, propulsion and structures. I am involved in the project, where students are asked to come up with a preliminary design for an aircraft, and in the course Aircraft Structures.

- Phase Transformations in Manufacturing (202100319) The course on phase transformations in manufacturing provides deeper understanding of the thermodynamics and kinetics of phase transformations in metals, alloys, polymers and thermoplastic composites during molding/forming processes. I provide a lecture and assignments on the role of phase transformations in thermoplastic composites.

- Supervisor for Academic Research Skills, and BSc & MSc Assignments The assignments are related to ongoing research projects on the manufacturing and performance of composites and typically involve both theoretical and experimental work. Topics can range from heat transfer modelling for induction welding to the design of an experimental setup to characterize the performance of high performance composites. Feel free to drop by and ask about the possibilities in case you are interested in a challenging research assignment in the field of composite materials.

Affiliated study programs

Courses academic year 2025/2026

Courses in the current academic year are added at the moment they are finalised in the Osiris system. Therefore it is possible that the list is not yet complete for the whole academic year.

Courses academic year 2024/2025

- 191121700 - Composites Forming

- 191121710 - Composites

- 191121730 - Production Technology - Capita Selecta

- 191199154 - Internship

- 195799152 - Internship

- 202000158 - Minor Aircraft Engineering

- 202000247 - Frontiers to High-Tech Systems&Materials

- 202000250 - Internship

- 202100319 - Phase transformations in manufacturing

Address

University of Twente

Horst Complex (building no. 20), room N208

De Horst 2

7522 LW Enschede

Netherlands

University of Twente

Horst Complex N208

P.O. Box 217

7500 AE Enschede

Netherlands